Understanding Engineering Capability in Modern Industrial Projects

What increasingly determines whether projects deliver smoothly or unravel late is engineering capability. It specifically refers to the depth of technical understanding, process integration, and judgement applied across the full lifecycle of a job. This shift is subtle, but it is reshaping how experienced engineering buyers evaluate risk, reliability, and long-term value.

In many industrial sectors, project success is still too often judged by capacity: how quickly work can start, how many machines are available, or how short the quoted lead time appears on paper. Yet as engineering projects grow more complex, regulated, and interconnected, these surface-level indicators are proving unreliable.

What Engineering Capability Actually Means Today

Engineering capability is frequently misunderstood as a proxy for scale or throughput. In practice, it is something quite different.

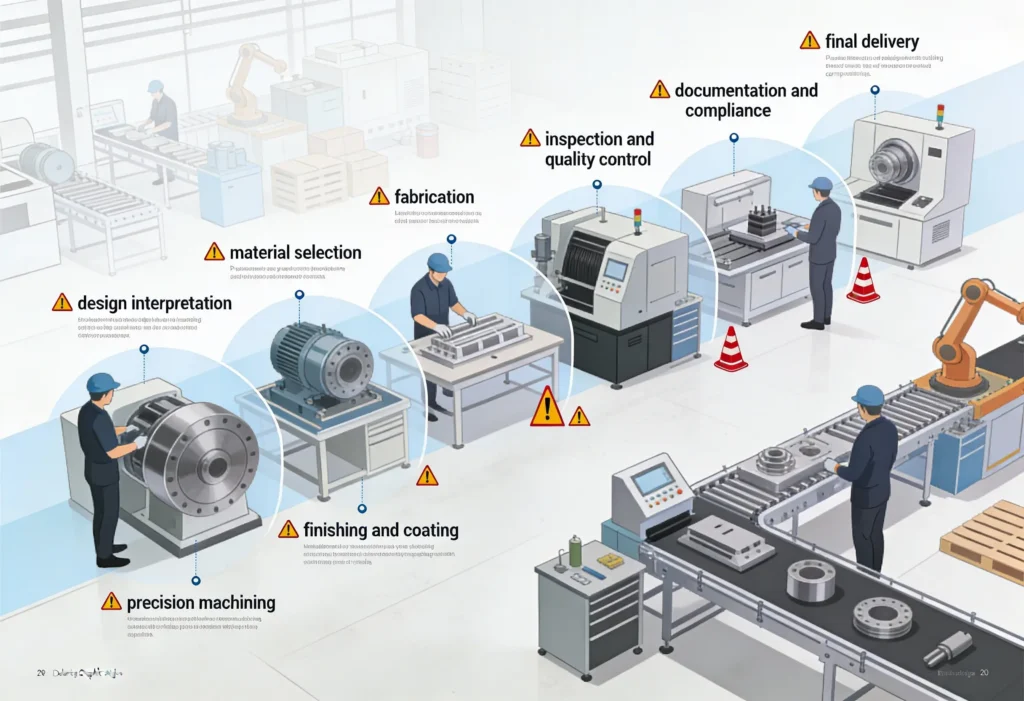

At its core, engineering capability reflects an organisation’s ability to manage complexity across multiple dimensions at once: materials, tolerances, finishing requirements, compliance, documentation, and change. It encompasses not just what can be manufactured, but how confidently challenges can be anticipated, absorbed, and resolved without disrupting delivery.

Unlike capacity, which can fluctuate quickly, engineering capability is built slowly through experience, systems, and integrated processes. In modern industrial environments, that distinction matters more than ever.

Why Capacity Alone No Longer Guarantees Delivery

For many years, manufacturing models prioritised speed and volume. If one supplier became constrained, work could be shifted elsewhere with minimal disruption. That assumption no longer holds in sectors where regulation, quality assurance, and specialist processes dominate.

As discussed in earlier analysis on delivery risk, “Why Engineering Lead Times Are Becoming a Strategic Risk“, delays now emerge less from machine availability and more from downstream constraints that are difficult to compress once a project is underway.

In this context, engineering capability, and not headline capacity, has become the more reliable predictor of delivery confidence.

Engineering Capability and Risk Ownership

Every engineering project carries risk. What changes from one programme to another is where that risk ultimately sits.

Organisations with limited engineering capability tend to push uncertainty downstream. Problems are discovered late, rework becomes unavoidable, and responsibility for resolution is fragmented across suppliers. By contrast, strong engineering capability allows risk to be identified earlier and managed deliberately.

This difference is rarely visible at the quotation stage. It becomes apparent only when tolerances tighten, specifications evolve, or compliance requirements intersect with production realities. At that point, capability and not intent determines the actual outcomes.

Where Engineering Capability Is Truly Tested

Engineering capability is most clearly revealed at the points where projects are least forgiving. Finishing, coatings, advanced materials, and multi-process components expose weaknesses quickly.

Issues such as tolerance stack-up, surface preparation, or late-stage design clarification rarely exist in isolation. They compound across handovers, particularly when work is split across multiple suppliers. These dynamics were explored in more detail in earlier discussion of delivery friction “The Hidden Engineering Bottlenecks Slowing Down Projects“.

Strong engineering capability does not eliminate these challenges, but it reduces their impact by recognising them as system-level risks rather than isolated defects.

How Integrated Engineering Capability Improves Predictability

One of the clearest ways to strengthen engineering is through integration. When machining, fabrication, finishing, and inspection are planned as part of a single delivery framework, constraints surface earlier and trade-offs can be evaluated before they harden into delays.

Integrated capability does not imply doing everything in-house at any cost. It means having the technical oversight, process control, and coordination necessary to manage interfaces intelligently. This approach reduces the accumulation of small uncertainties that so often undermine predictability.

Examples of integrated engineering services can be seen across PRV’s broader capabilities, where multiple processes are aligned around delivery rather than treated as independent steps.

Engineering Capability Across High-Risk Sectors

The importance of engineering capability is most apparent in sectors where failure carries significant consequences. Defence, aerospace, rail, energy, and critical infrastructure projects operate under conditions where compliance, traceability, and reliability are non-negotiable.

In these environments, the cost of rework extends beyond time and money. It affects certification, safety margins, and long-term asset performance. As a result, buyers increasingly prioritise partners who demonstrate consistent engineering capability rather than simply offering competitive lead times.

This trend reflects a broader shift across UK manufacturing, where complexity and regulation continue to rise. Industry data from Make UK highlights ongoing pressure on capacity and supply chains, reinforcing the need for predictability rather than speed alone.

What Engineering Buyers Are Quietly Prioritising

Although rarely stated explicitly, procurement behaviour is changing. Many engineering buyers are consolidating supplier lists, extending relationships, and favouring organisations that can absorb complexity without escalation.

This is not a move away from efficiency. It is a recognition that engineering capability reduces hidden costs: programme disruption, management overhead, and late-stage compromise. Over time, these factors outweigh marginal differences in unit price or nominal lead time.

As projects become more interconnected, capability has become a form of insurance; one that is difficult to quantify upfront, but immediately visible when conditions change.

Engineering Capability as a Source of Certainty

Modern engineering projects do not fail because complexity exists. They fail when complexity is underestimated or poorly managed. Engineering capability provides the structure through which uncertainty can be controlled rather than reacted to.

For organisations delivering work across defence, aerospace, rail, construction, energy, and automotive sectors, this capability underpins confidence at every stage; from design interpretation through to finishing, compliance, and final handover.

PRV Engineering supports complex programmes by aligning machining, fabrication, specialist processes, and finishing within a coordinated delivery environment. This emphasis on engineering capability helps reduce uncertainty, improve predictability, and support delivery outcomes as project demands continue to rise.

Contact us for more information or to discuss your project requirements.

Recent Comments